How to Pick the Right Thickness of Wear Resistant Steel Sheet?

Picking the right thickness for a wear resistant steel sheet is super important. It helps make sure the sheet lasts long and is cost – effective in industrial use. Several key things affect this choice. First, think about how much wear the sheet will face.

If it’s for light or medium – wear situations, like conveyor systems that move non – abrasive stuff, thinner sheets might work. But in tough places like mines or construction sites, you need thicker sheets. These can handle long – term impact and abrasion.

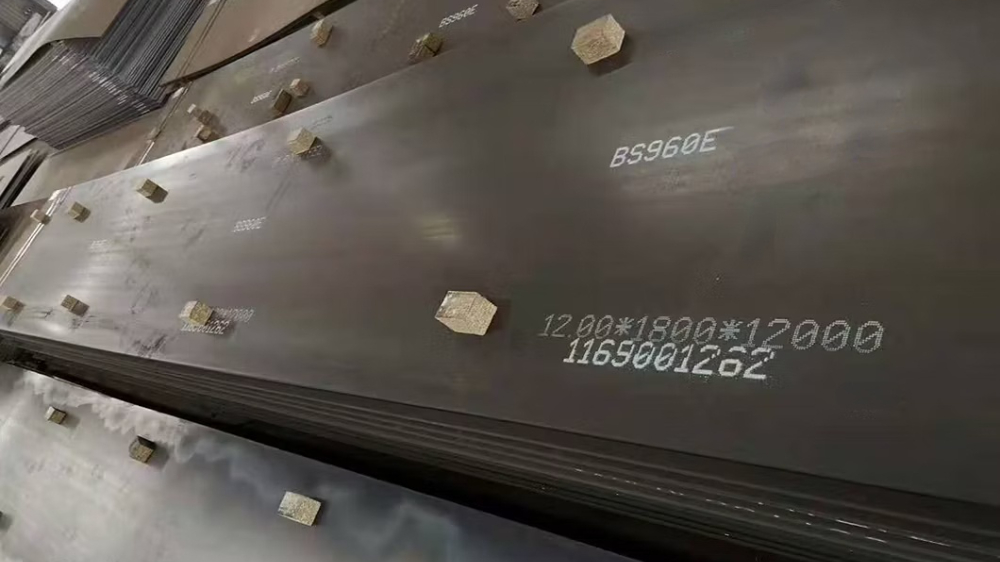

Wear resistant metals, including different grades of wear resistant steel, have different performance features. These features matter when choosing the thickness. Take the Nm400 wear resistant steel plate, for example. It’s a well – known grade. It’s hard and tough. You can use a moderately thick sheet of it for good protection. This way, you can cut down on the overall weight without losing wear resistance. It’s vital to match the steel grade with the thickness. Higher – grade wear resistant plates can often be a bit thinner because of their better material properties.

Another big factor is the operating load and how often there are impacts. In high – impact jobs, you need thicker sheets. They can soak up energy and stop the sheet from deforming too early. Also, think about the structural support. Thinner sheets might need extra support, while thicker ones are stable on their own.

Always check the material details and application rules. You want to balance the thickness with how well the sheet performs. If you choose a sheet that’s too thick, you’ll spend more money than you need to. If it’s too thin, it won’t last as long. By thinking about all these things, you can pick the best thickness of wear resistant plate for your needs.

Post time: Jan-09-2026