-

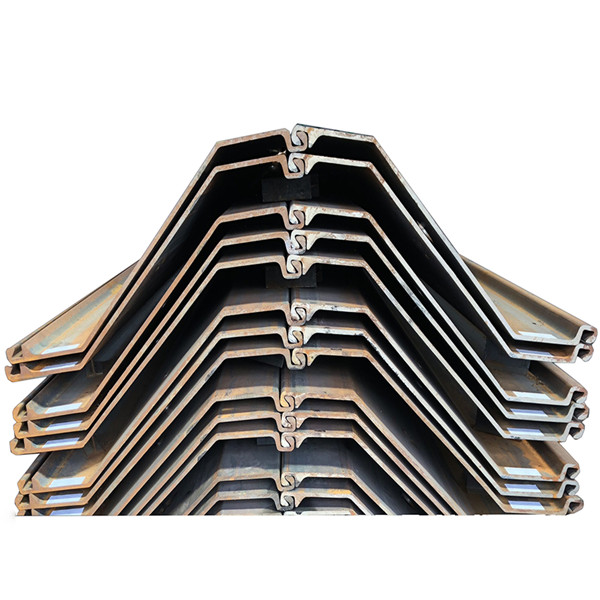

SY295 Hot Rolled U Steel Sheet Pile For Construction

SY295 Hot Rolled U Steel Sheet Pile For Construction -

PVC Sheet Pile Plastic Vinyl Piling Manufacturer For Retaining Walls

PVC Sheet Pile Plastic Vinyl Piling Manufacturer For Retaining Walls -

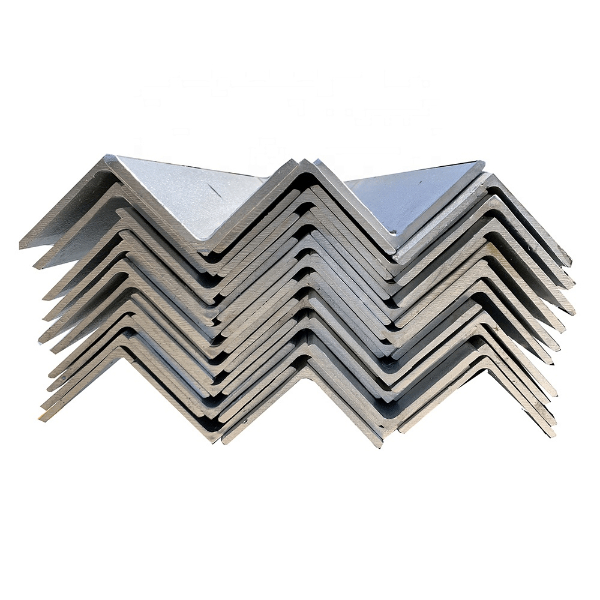

Hot dipped Galvanized Lintel Gi Steel Angle Bar For Construction

Hot dipped Galvanized Lintel Gi Steel Angle Bar For Construction -

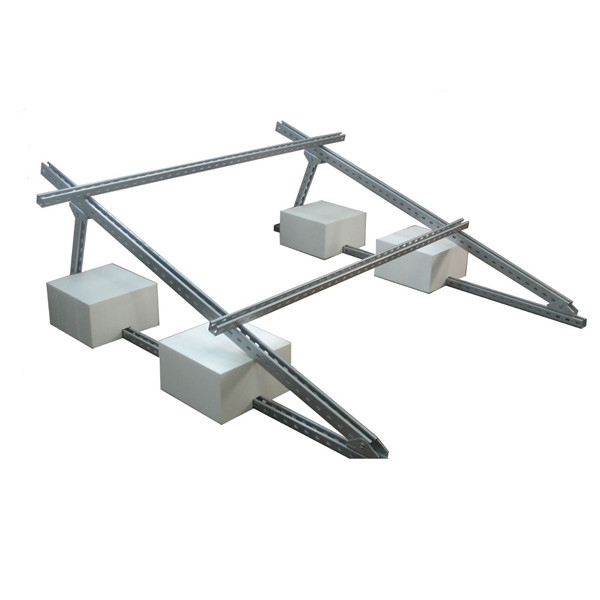

Solar Tracking Photovoltaic Support Bracket With Solar Panel

Solar Tracking Photovoltaic Support Bracket With Solar Panel -

Galvanised Steel Retaining Wall Post For Australia

Galvanised Steel Retaining Wall Post For Australia -

Hot rolled Z steel sheet piles

Hot rolled Z steel sheet piles -

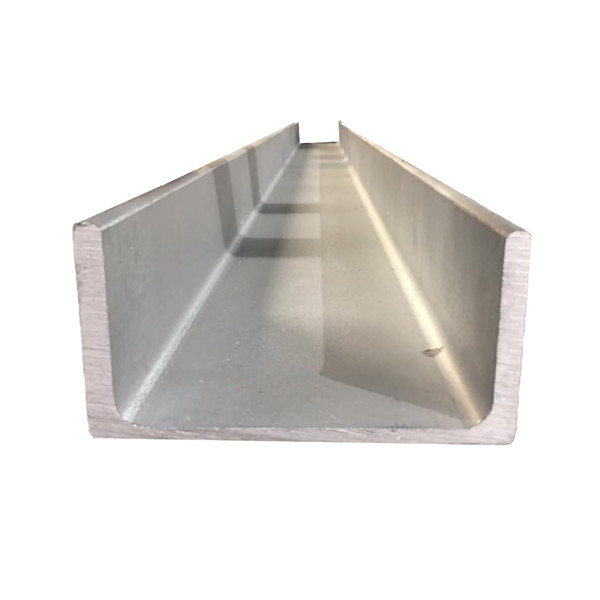

Steel U Channel ASTM a36 For Australia

Steel U Channel ASTM a36 For Australia -

Cold Formed Z Steel Sheet Pile For Construction

Cold Formed Z Steel Sheet Pile For Construction -

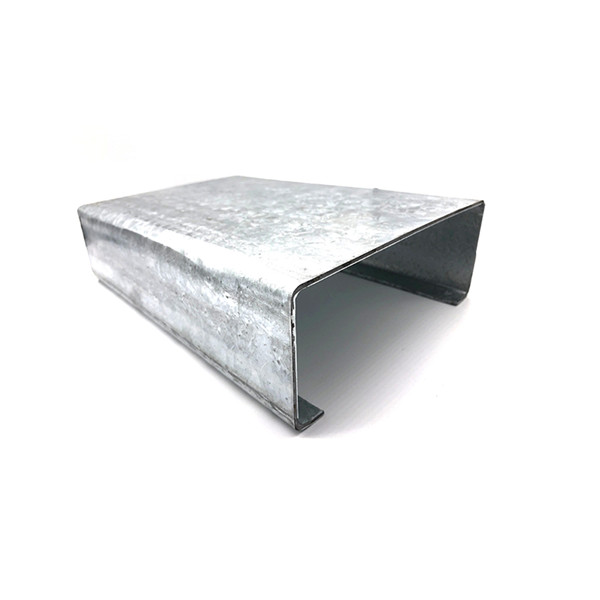

Gi Steel C Purlin For Solar Tracker

Gi Steel C Purlin For Solar Tracker -

Steel Flat Bar Q235B For Construction

Steel Flat Bar Q235B For Construction -

Steel i Beam 36a Size For Construction

Steel i Beam 36a Size For Construction -

Steel Round Bar For Making Tools

Steel Round Bar For Making Tools