What is the impact of surface defects on galvalume steel coils?

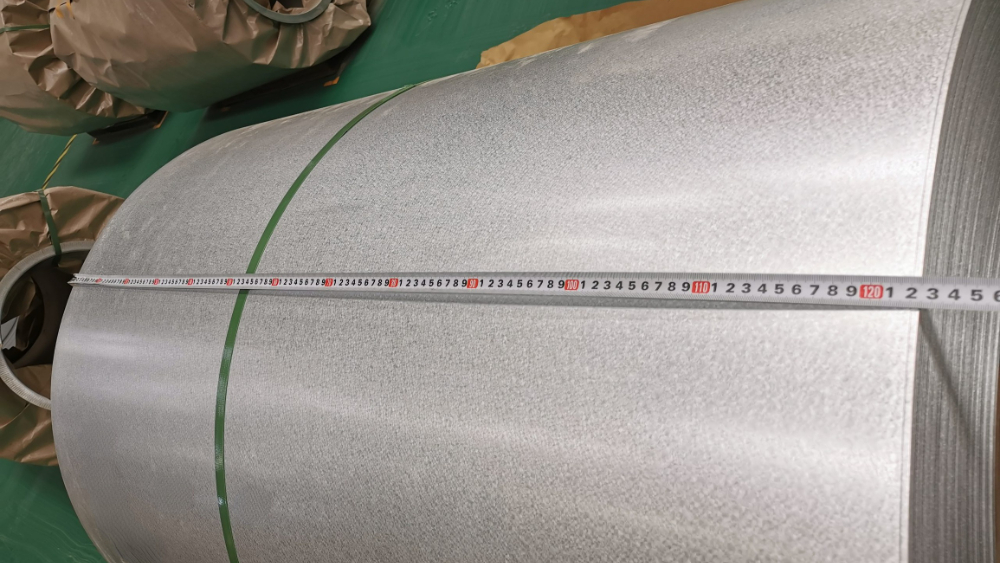

When it comes to the durability and performance of galvalume steel coil, surface defects can significantly affect its overall performance. Galvalume steel coil products, such as the popular galvalume steel coil AZ150, are known for their superior corrosion resistance and long life. However, even the slightest surface defect can compromise these advantages.

Surface defects in aluzinc galvalume steel coil, including scratches, dents, or uneven coatings, can lead to premature rust and corrosion. This is particularly concerning for industries that rely on high-quality materials, such as construction and manufacturing. Galvalume coil suppliers emphasize the importance of quality control to ensure their products meet stringent standards. A defect-free surface is essential to maintaining the integrity of the protective aluzinc coating, which is a major feature of galvalume steel coils.

Additionally, surface defects can affect the aesthetics of the final product. For builders and manufacturers, the visual quality of a material is just as important as its functional properties. Perfect galvalume roll not only enhance the appearance of a building structure, but also demonstrate the customer’s commitment to quality.

When considering galvalume steel coil price, it is important to factor in the potential costs of surface defects. Purchasing high-quality steel coil galvalume from a reputable supplier can save costs in the long term by reducing the need for maintenance and replacement.

All in all, the impact of surface defects on galvalume steel coils cannot be underestimated. For those who need galvalume steel coils or galvalume steel coil products, choosing a reliable galvalume steel coil supplier can ensure that you get materials that meet the highest performance and durability standards. Don’t compromise on quality – choose galvalume steel coils that combine strength and beauty.

Post time: Jul-02-2025