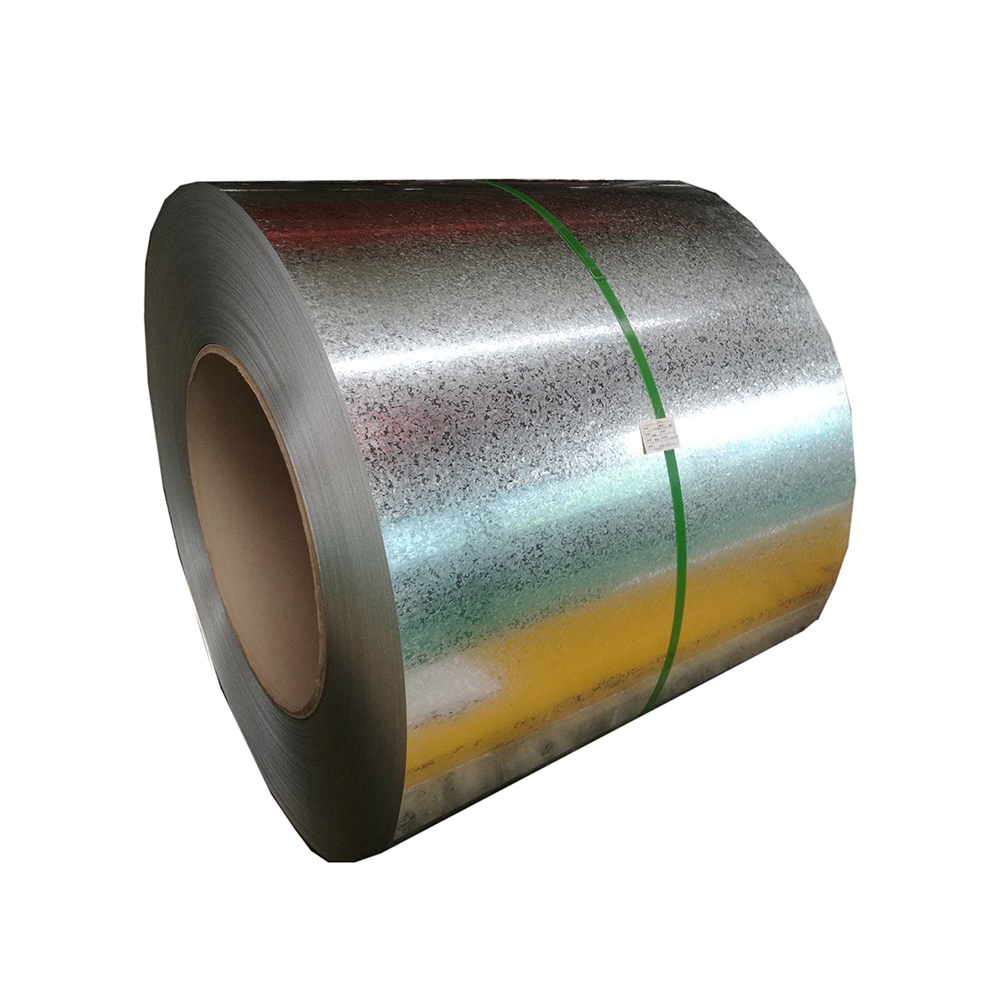

Premium Galvalume Coil for Superior Project Performance

Premium Galvalume Coil for Superior Project Performance

Feature

-

The G550 galvanized zinc steel coil features a unique aluminum-zinc alloy structure. It is formed by compounding and curing 55% aluminum, 43.4% zinc and 1.6% silicon at a high temperature of 600℃. It is an important alloy material widely used in daily production and construction.

This product boasts outstanding performance: its corrosion resistance can exceed that of ordinary pure galvanized sheets by more than three times; the surface features a beautiful zinc texture, providing long-term protection while also being suitable for decorative surfaces such as building exteriors, achieving a balance between functionality and aesthetics.

1. Execution standard: Supports international standards such as AISI, ASTM, BS, DIN, GB, JIS, etc.

2. Material grade: Standardly equipped with G550 or customized at other grades according to customer requirements.

3. Specification basis: Complies with JIS3321 / ASTM A792M specification requirements.

4. Thickness range: 0.16mm - 2.5mm, all specifications can be customized.

5. Width selection: Can be customized for production according to customer requirements.

6. Board length setting: Set according to the specific usage requirements of the customer.

7. Inner diameter of the roll: Standard 508mm / 610mm (Support customization of special inner diameters).

8. Weight setting of the roll: Supports setting according to the customer's usage requirements.

9. Coating specification: Aluminum zinc coating covering AZ50 to AZ180.

10. Zinc flake type: Regular zinc flake, small zinc flake, and large zinc flake are available.

11. Surface treatment: Chemical treatment, oil, dry, Chemical treatment and oil, anti-finger print.

| Steel Type | AS1397-2001 |

EN 10215-1995 |

ASTM A792M-02 |

JISG 3312:1998 |

ISO 9354-2001 |

|

Steel for Cold Forming and Deep Drawing Application |

G2+AZ |

DX51D+AZ |

CS type B, type C |

SGLCC |

1 |

|

G3+AZ |

DX52D+AZ |

DS |

SGLCD |

2 |

|

| G250+AZ |

S25OGD+AZ |

255 |

- |

250 | |

|

Structural Steel |

G300+AZ |

- |

- |

- |

- |

| G350+AZ |

S35OGD+AZ |

345 Class1 |

SGLC490 |

350 | |

| G550+AZ |

S55OGD+AZ |

550 |

SGLC570 |

550 |

| Surface T reatment |

Feature |

| Chemical Treatment |

minimize the chance of humid-storage staining forms a dark gray surface discoloration on the surface |

|

retain the bright metallic luster for a long period |

|

| Oil |

minimize the tendency for humid-storage stain |

|

Chemical Treatment and Oil |

The chemical treatment provides very good protection against humid-storage staining, while the oil provides lubricity for operations. |

| Dry |

must be transported and stored with special precautions to preserve low-humidity conditions. |

| Anti-finger print |

minimize tlie chance of humid-storage staining forms a dark gray surface discoloration on the surface |

*The alloy composition of the galvanized zinc steel is 55% aluminium, 43.5% zinc and 1.5% silicon.

*This material exhibits excellent formability, weldability and coating suitability.

*Aluminum-zinc steel exhibits outstanding corrosion resistance in most atmospheric environments. This is attributed to the combined effect of zinc's cathodic protection and aluminum's physical barrier protection.

*The corrosion resistance of its coating is enhanced by 2 to 6 times compared to ordinary hot-dip galvanized steel sheets.

*We can provide direct supply services for finished products to our clients.

*We can handle the entire process of import clearance on their behalf.

*We have a deep understanding of the Philippine market and have established an extensive customer network.

*We enjoy a good business reputation and positive in the industry.

1. Construction field: Applicable to roofs, walls, garages, soundproof walls, various pipes and modular buildings, etc.

2. Automotive manufacturing: Often used in mufflers, exhaust pipes, windshield wiper parts, fuel tanks, truck bodies, etc. components.

3. Household appliances: Widely used in refrigerator back panels, gas stoves, air conditioner shells, microwave ovens, LCD frames, CRT explosion-proof strips, LED backlight panels, electrical cabinet bodies, etc.

4. Agricultural facilities: Applicable to livestock farms, poultry houses, grain warehouses, greenhouse pipes, etc. agricultural buildings.

5. Other uses: Can be applied to heat insulation covers, heat exchangers, drying equipment, water heaters, etc. industrial and civilian products.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION