1050 Aluminum Pipe For Automobile

1050 Aluminum Pipe For Automobile

Feature

-

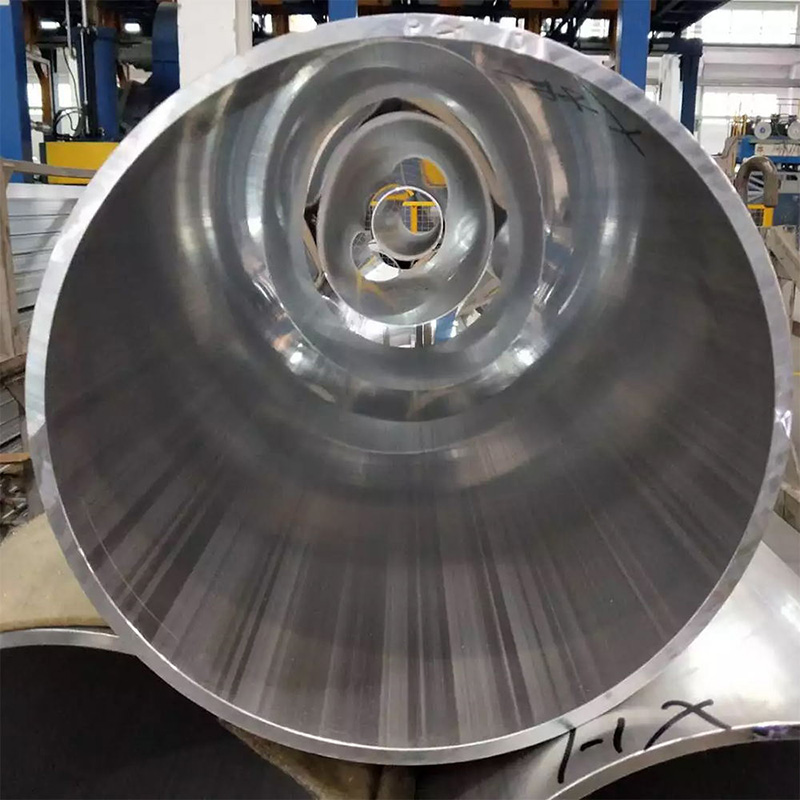

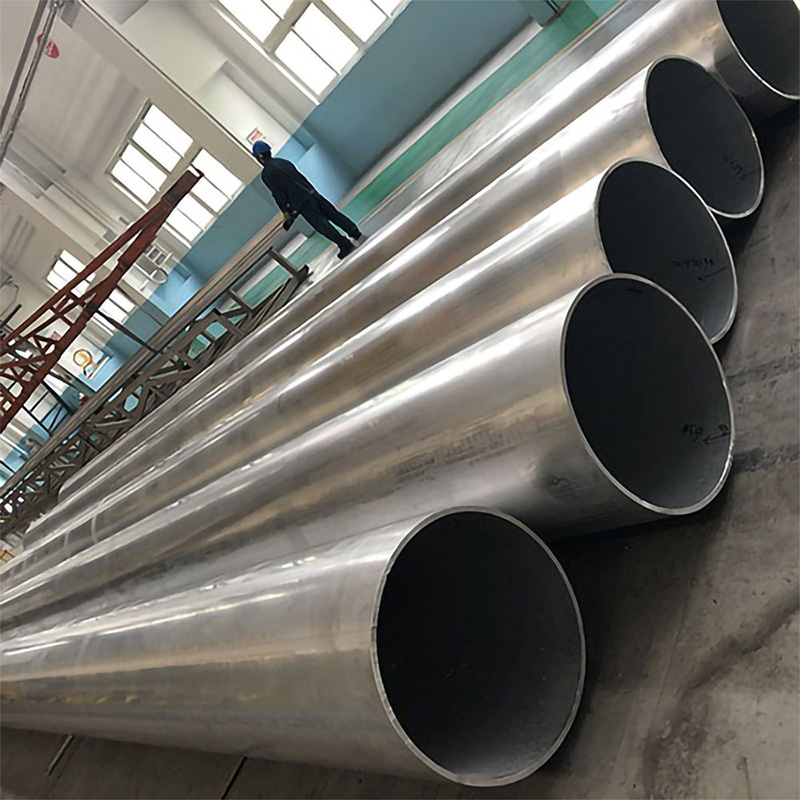

Aluminum pipe is a kind of non-ferrous metal pipe, which is made of pure aluminum or aluminum alloy and extruded into hollow metal tubular material along its longitudinal length.

According to the extrusion method, it is divided into seamless aluminum pipe and ordinary extruded pipe

According to precision: ordinary aluminum tubes and precision aluminum tubes, among which precision aluminum tubes generally need to be reprocessed after extrusion, such as cold drawing, fine drawing and rolling.

Divided by thickness: ordinary aluminum pipe and thin-walled aluminum pipe

Performance: corrosion resistance, light weight.

1)Grade:1000, 3000, 5000, 6000, 8000 series

2)Temper: F, O, H12, H14, H16, H18, H22, H24, H26, H28

3)Surface treatment: Powder coating, Color Anodizing, Sand Blasting, Brushing, CMP

4)Type: round, square, rectangular or customized

5)Color:Nature, silver, bronze, champagne, black, gloden, etc.

6)Size: 1.Round tube diameter:9.5-250 mm (customized)

2. Square:19*19-140*140mm

3. Rectangular:28*19.5-150*100mm

7)Wall Thickness:0.5-20 mm (customized)

8)Length: customized

9)Processing Service: punched

First, the advantages of welding technology: the welding technology of thin-walled copper-aluminum pipe, which is suitable for industrial production, is called a world-class problem, and is the key technology of replacing copper with aluminum for connecting pipe of air conditioner.

Second, the advantage of service life: from the perspective of the inner wall of the aluminum pipe, because the refrigerant does not contain water, the inner wall of the copper-aluminum connecting pipe will not corrode.

Third, energy-saving advantage: the lower the heat transfer efficiency of the connecting pipeline between the indoor unit and the outdoor unit of the air conditioner, the more energy-saving it is, or the better the heat insulation effect, the more energy-saving it is.

Fourth, it has excellent bending performance and is easy to install and move

Aluminum pipes are widely used in all walks of life, such as automobiles, ships, aerospace, aviation, electrical appliances, agriculture, electromechanical, household, etc. Aluminum pipes are ubiquitous in our lives.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION