A463 Aluminized Hot Dip Aluminum Coated Steel Coil

A463 Aluminized Hot Dip Aluminum Coated Steel Coil

Feature

-

Hot-dip aluminum coated steel coil combines the mechanical properties of cold-rolled steel coil with aluminum’s high resistance retention, heat reflection, and superior rust resistance.

1.Material: ASTM A463, SA1C,SA1D,SA1E,DX54D, DX56D, etc.

2.Thickness: 0.25-0.8mm

3.Width: from 800mm to 1250mm, all available

4.Coil Weight: from 3-8MT, according to the customer's request

5.AS coating: 12-25μm

6.Post-treatment type:Oiled, Non treatment

7.Technology: Hot Dipped

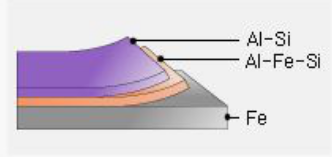

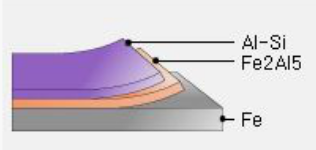

8.Coating Layers of hot dip aluminium coated steel:

>>Heat resistance: Lengthy exposure to temperatures up to 450 degrees Celsius causes very little change in ALCOAT and does not affect its attractive surface brightness, compared to galvanized steel coil and cold-rolled steel coil.

>>Heat Reflectivity: Elegant surface of ALCOAT reflects about 80% of the heat at a temperature of 450 degrees Celsius. Its reflection rate goes up to 95% where infrared rays are present. This makes ALCOAT the ideal choice for producing the heat reflector plates in toasters, ovens, gas ranges and oil stoves.

>>Corrosion resistance: Aluminum tends to be more resistive than Mn, Mo, Cr, W, Cd, Fe, Zn. But because the aluminum oxide film itself has good stability, so the surface corrosion resistance in addition to part of the environmental conditions, much better than galvanized coil.

>>Green environmental performance: It's not harmful to human body, is an environmental protection product, aluminum plating plate can be fully recycled

>>Processing performance: Aluminized steel plates can be processed in the same way as other steel plates

>>Weldability: Because aluminum is soft, it is easy to bond, and because of its strong electrical conductivity, the welded part has excellent heat dissipation. In addition, because the coating is higher than the galvanized melting point, it is not easy to flow, and the melting area is small, so it is not necessary to use galvanized steel plate as high current

>>Surface appearance: It has a long-lasting shine, better corrosion resistance and weathering resistance.

1)Automotive components : muffler, exhaust pipe, fuel tank

2)Appliances : Electric stove, gas range, bread machine, toaster, frying pan, dryer, air conditioner, heat exchanger, stovepipe, pre-heater, dryer, duct, boiler, gas oven, rice cooker.

3)Construction : Walls and roofs of chemical factories, fireproof walls

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION