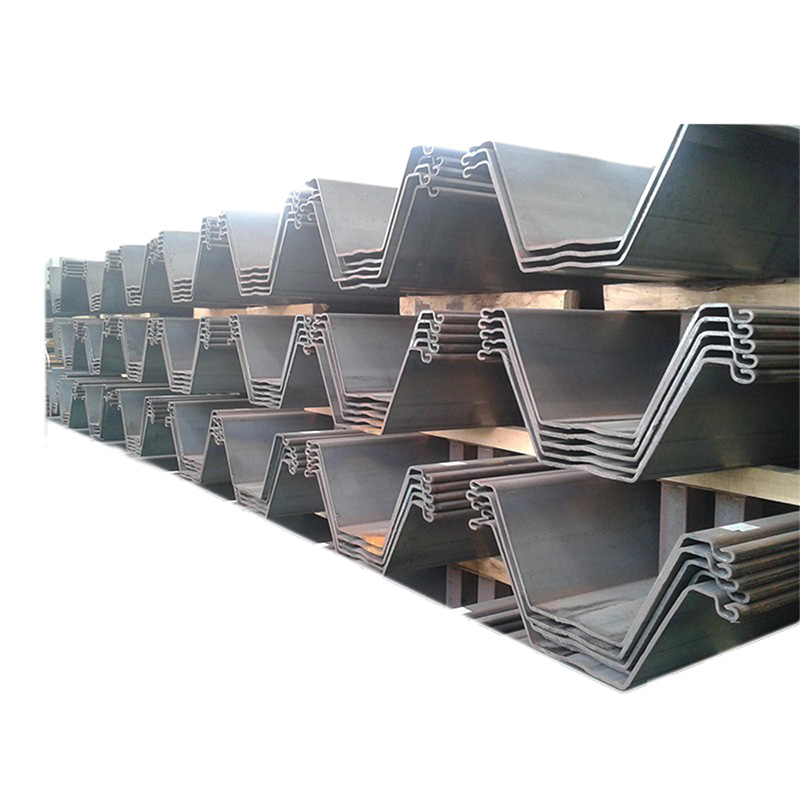

Cold Formed U Steel Sheet Pile For Project

Cold Formed U Steel Sheet Pile For Project

Feature

-

Cold formed U type steel sheet piles’ process is: a steel billet is heated and rolled in the same manner as hot- rolled sheet pile, but instead of being shaped into the U sheet pile sections while hot, the coils are left to cool. The hot-rolled coils are then run through a mill and shaped at room temperature into the final U shape.

1)Place of Origin: Tianjin, China (Mainland)

2)Brand Name: ZHANZHI

3)Standard: EN10249

4)Type: u type sheet pile

5)Technique: cold formed

6)Length: Any Length

1) The width of the section is large, which ensures that the mechanical properties of the section are fully exerted.

2) The structure is symmetrical and easy to reuse.

3) The design of product cross-section structure is reasonable and has a high "quality factor"

4) The use of steel sheet piles can not be restricted by weather conditions.

5) The construction has obvious environmental protection effect, which greatly reduces the amount of soil taken and the amount of concrete used, and effectively protects the land resources.

6) Green and environmental protection.

7) More readily available: Cold-Formed sheet piles are produced at higher quantities than hot-rolled sheet piles, increasing the number of rolling dates to choose from. Typical production time is 2 weeks.

8) Cost-effective: Cold-Formed sheet pile is about 30-40% less expensive to produce than hot-rolled sheet pile.

9) Less expensive to transport: Due to the larger number of cold- formed sheet pile manufacturers, there is a higher chance that you can find a mill located nearby than if you were to purchase hot- rolled sheet piles. Additionally, the larger selection of cold-formed sheet piles may allow you to find sections with a section modulus closer to your design specifications without a large increase in weight.

10) More flexibility in positioning: Cold-formed sheet pile interlocks allow for a 25-degree rotation, rather than the 7-to-10-degree rotation allowed with hot-rolled sheet pile using ball-and-socket interlocks.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION