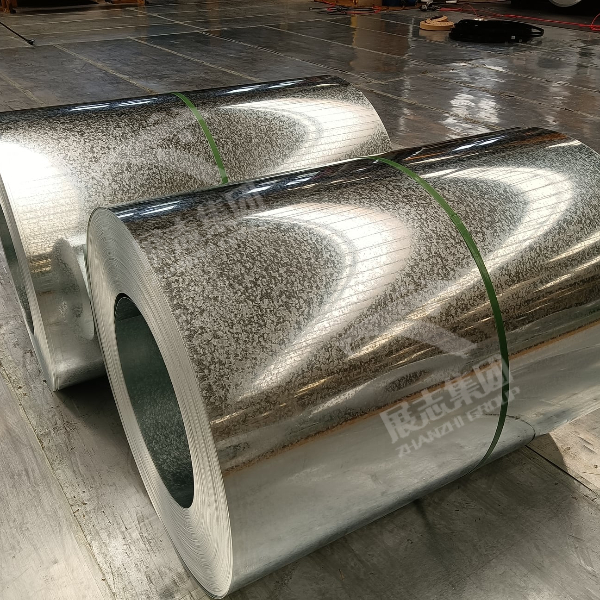

Galvanized Steel Coils – Durable Coated Sheet Metal

Galvanized Steel Coils – Durable Coated Sheet Metal

Feature

-

Hot-dipped galvanized steel coil provides superior corrosion protection and enhanced strength for enduring structural performance. This is the resulting of immersion of steel in molten zinc at temperature about 500C, it gives a clean and uniform layer, ideal for industrial and architectural uses.

1. Specification Compliance: Meets international standards including AISI, ASTM, BS, DIN, GB, and JIS.

2. Material Grade: Available in DX51D and other grades based on customer specifications.

3. Quality Standards: Certified under JIS3321 / ASTM A792M standards.

4. Thickness Range: Offered from ultra-thin 0.16mm up to 2.5mm.

5. Width Options: Fully customizable to fit precise project dimensions.

6. Cutting Length: Can be slit and cut to exact length requirements.

7. Inner Diameter: Standard coil ID of 508mm or 610mm (20" or 24").

8. Coil Weight: Customizable to optimize logistics and handling.

9. Zinc Coating: Coating weight adjustable from 30g/m² to 275g/m².

10. Surface Finish: Available in zero, small, regular, or large spangle.

11.Packing: standard sea-worthy packing

The surface oxidation resistance of galvanized steel coil is strong, which can strengthen the anti-corrosion penetration ability of parts.

1. The surface of galvanized steel coil with superior rust resistance is greatly beneficial to improve the anti-corrosion ability of component.

2. Provides an economical processing and fabricating solution.

3. The stainless galvanized steel coil is long-time used and long-time expectant.

4. The galvanized steel coil has difficult toughness resist and adhesive power.

5. Zinc plating is applied to the two surfaces and even to the inner crevices, sharp corners and blind holes of the part, the zinc plating can protect the part completely.

6. The galvanizing treatment for galvanized steel coil is quicker than many other coating methods, removing the time for painting after the installation on site.

7. Hot-dip galvanizing is usually more economical and longer-lasting than alternative coatings.

8. There is no problem with quality control: The hot-dip zinc reforrned layer on galvanized steel coil can be seen, and thickness can be measured by non-destructive coating thickness gauge.

1. Building & Construction Due to its excellent durability and corrosion resistance, this is the most popular choice for roofing, wall cladding, garages, industrial sound barriers, ductwork and community hall designs.

2. Automotive Production Necessary for such parts as mufflers, exhaust systems, wiper components, fuel tanks, and truck bodies, which must be rust and weather resistant.

3. Manufacturing of Home Appliances: It is widely used in refrigerator panels, oven shells, air conditioner shells, microwave oven shells, TV mainframes, LED parts and electrical casing to provide a clean and protective coating.

4. Agronomy Reasons to buy: Used for animal housing (poultry/pig farms) and grain storage silos, greenhouse structures, and irrigation systems, it delivers sustainable service for even the most demanding applications.

5. General and Industrial Products Production of thermal insulation jackets, heat exchangers, drying drums, water heater tanks and an assortment of custom fabrications needing surface security that can be trusted.

Perfect packing

Delivery by Container

Delivery by bulk cargo

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION