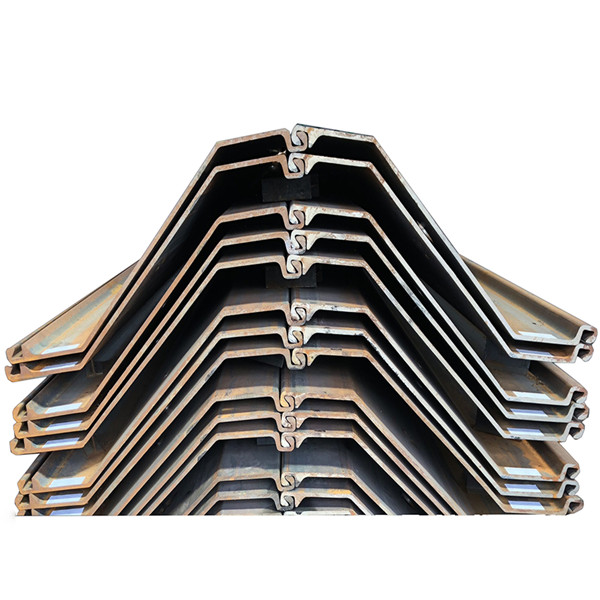

Hot rolled Z steel sheet piles

Hot rolled Z steel sheet piles

Feature

-

Hot rolled Z type steel sheet piles’ locks are symmetrically distributed on both sides of the neutral axis, and the webs are continuous. The process of hot rolled z steel sheet pile is : Hot rolled steel has been pressed at temperatures over 1,700F, which makes it easier to shape and form. Here’s a look at the production process for hot-rolled steel sheet pile: 1.A large rectangular beam, called a billet, is heated and flattened into a large roll 2.The roll of steel is run through a series of rollers, still at extremely high temperatures, to achieve the desired dimensions and shape.

1)Place of Origin: Tianjin, China (Mainland)

2)Brand Name: ZHANZHI

3)Material:SY295/SYM295 or SY390/SYM390

4)Standard: JIS

5)Type: Z type sheet pile

8)Technique: Hot rolled

9)Length: Any Length

10)The Z shaped steel sheet pile presents the following advantages:

●Extremely competitive section modulus

●Economical solution

●Large width resulting in high installation performance

●High tensile strength

●ldeal for permanent structure project

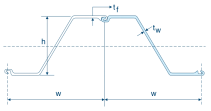

Some hot rolled Z steel sheet pile size

Locks of hot rolled z type steel sheet piles are symmetrically distributed on both sides of the neutral axis, and the web is continuous, which greatly improves the section modulus and bending stiffness, and ensures that the mechanical characteristics of the section can be fully exerted.

1)More durable interlocks: This allows the sheets to be driven and pulled many times before the interlocks are worn out

2)Better-suited for hard pile driving: The interlocks on hot-rolled sheet piles are also thicker and tighter than that of cold-rolled sheet pile. This gives the sheet piles greater strength to be driven into tough ground conditions

3)Higher recycled steel content: LEED requirements sometimes dictate the use of recycled materials. Hot-rolled sheet piles have almost 100% recycled steel content, while cold-formed sheet piles typically consist of around 80% recycled material

4)More water-tight: Hot-rolled sheet piles perform better in seepage tests, due in large part to the tighter interlocks

Hot rolled Z steel sheet pile is widely use in flood project, construction project, wharf construction and so on.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION