High-tech applications, wear-resistant steel plates lead the industry

Wear-resistant steel plate has become a revolutionary solution for the manufacturing industry, leading the way in delivering high-tech applications. With their exceptional wear resistance, these steel plates have become an integral part of various industries that require strong and durable materials to withstand harsh environments and heavy use.

One of the most well-known types of Wear Resistant Tool Steel plates is High Wear Resistance Steel. This type of steel is specifically designed to have excellent toughness and wear resistance, making it ideal for applications involving high levels of wear. From mining machinery to construction equipment, highly wear-resistant steel has proven its worth by extending the life of these important tools.

Another important variant is Wear Resistance Steel Plate, which is specifically designed to resist wear caused by cutting, grinding, and other similar operations. This type of steel is widely used in the manufacture of tools and molds in industries such as automotive, aerospace and engineering. Wear-resistant tool steel ensures tools can withstand continuous use and remain sharp, increasing productivity and reducing downtime.

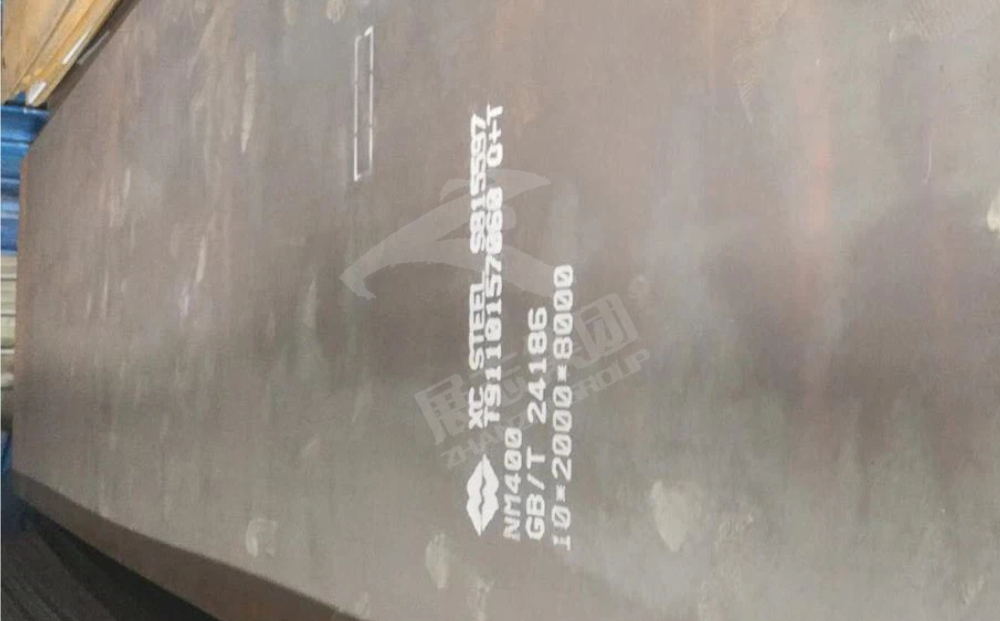

Speaking of wear-resistant steel plates, Nm400 wear-resistant steel plate is particularly worth mentioning. Known for its exceptional toughness and hardness, the plate has excellent wear and impact resistance. It is widely used in industries such as mining, construction and material handling where heavy machinery and equipment are subject to severe wear and tear.

There is no doubt that wear-resistant steel plates have revolutionized the industry with their unparalleled durability and longevity. They have become the first choice for applications requiring high strength, toughness and wear resistance. Not only do these sheets increase equipment performance and service life, they also significantly reduce maintenance costs.

To sum up, wear-resistant steel plates have become an indispensable part of various industries with their high-tech applications. From highly wear-resistant steels to wear-resistant tool steels and superior Nm400 Wear Resistant Steel Plate, these materials are pushing the boundaries of durability and performance. As technology continues to advance, we can expect further innovations in wear-resistant materials, revolutionizing the industry and ensuring a more sustainable future.

High-tech applications, wear-resistant steel plates lead the industry

Wear-resistant steel plate has become a revolutionary solution for the manufacturing industry, leading the way in delivering high-tech applications. With their exceptional wear resistance, these steel plates have become an integral part of various industries that require strong and durable materials to withstand harsh environments and heavy use.

One of the most well-known types of Wear Resistant Tool Steel plates is High Wear Resistance Steel. This type of steel is specifically designed to have excellent toughness and wear resistance, making it ideal for applications involving high levels of wear. From mining machinery to construction equipment, highly wear-resistant steel has proven its worth by extending the life of these important tools.

Another important variant is Wear Resistance Steel Plate, which is specifically designed to resist wear caused by cutting, grinding, and other similar operations. This type of steel is widely used in the manufacture of tools and molds in industries such as automotive, aerospace and engineering. Wear-resistant tool steel ensures tools can withstand continuous use and remain sharp, increasing productivity and reducing downtime.

Speaking of wear-resistant steel plates, Nm400 wear-resistant steel plate is particularly worth mentioning. Known for its exceptional toughness and hardness, the plate has excellent wear and impact resistance. It is widely used in industries such as mining, construction and material handling where heavy machinery and equipment are subject to severe wear and tear.

There is no doubt that wear-resistant steel plates have revolutionized the industry with their unparalleled durability and longevity. They have become the first choice for applications requiring high strength, toughness and wear resistance. Not only do these sheets increase equipment performance and service life, they also significantly reduce maintenance costs.

To sum up, wear-resistant steel plates have become an indispensable part of various industries with their high-tech applications. From highly wear-resistant steels to wear-resistant tool steels and superior Nm400 Wear Resistant Steel Plate, these materials are pushing the boundaries of durability and performance. As technology continues to advance, we can expect further innovations in wear-resistant materials, revolutionizing the industry and ensuring a more sustainable future.

Post time: Oct-23-2023