Understanding the anti-corrosion mechanism of hot-dip galvanized coil

When it comes to protecting steel from corrosion, hot dip galvanized coils are undoubtedly the top choice. But what exactly is the anti-corrosion mechanism behind these galvanized coils? Let’s delve deeper into the science and advantages that make hot-dip galvanized coils so popular among galvanized coil suppliers and manufacturers.

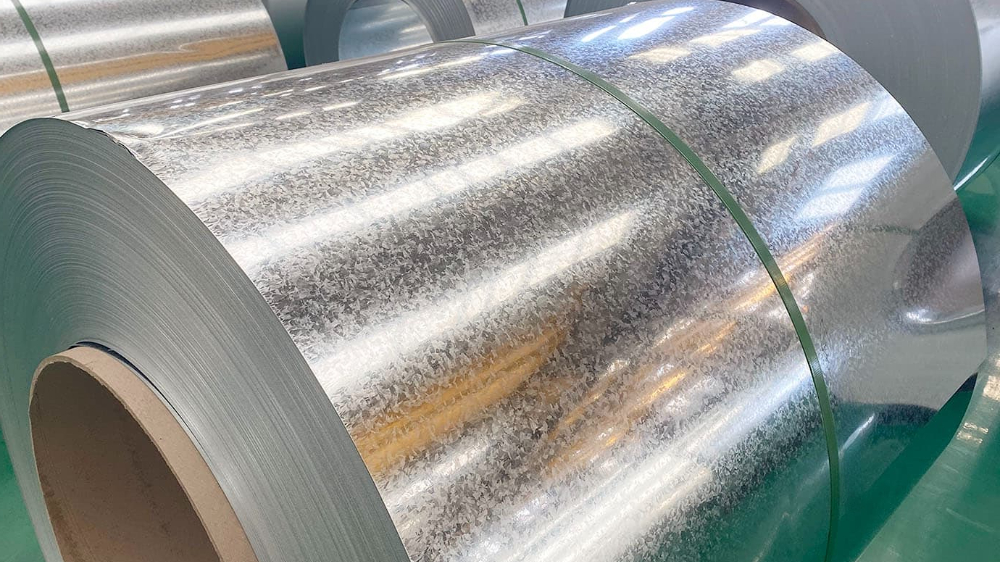

Hot dipped galvanized coil is produced by immersing steel in molten zinc, creating a strong, protective layer. This zinc coating acts as a sacrificial barrier, meaning it corrodes before the underlying steel. This unique mechanism is crucial for extending the life of steel, making galvanized coil an excellent investment for the construction, automotive, and manufacturing industries.

The galvanized coil price reflects the quality and durability this protective treatment brings. While the initial cost may be higher than non-galvanized options, the savings in maintenance and replacement costs over the long term make it a wise choice. When you choose hot-dip galvanized coil, you’re not just buying steel; you’re investing in a product that can withstand all kinds of weather, rust, and corrosion.

Furthermore, galvanized coil is highly versatile and can be used for everything from roofing to fencing. Galvanized coil suppliers offer a range of options to suit specific project needs, ensuring you find the most suitable product.

In short, the corrosion protection offered by galvanized steel coil has changed the industry landscape. Hot-dip galvanized coil, thanks to its protective zinc layer, offers unparalleled durability and longevity. So, whether you’re looking for galvanized coil stock for your next project or searching for a reliable galvanized coil supplier, remember that investing in quality galvanized coil is an investment in the future of your building. Don’t compromise on protection—choose hot-dip galvanized coil today!

Post time: Oct-24-2025