P20 Mold Steel For Casting

P20 Mold Steel For Casting

Feature

-

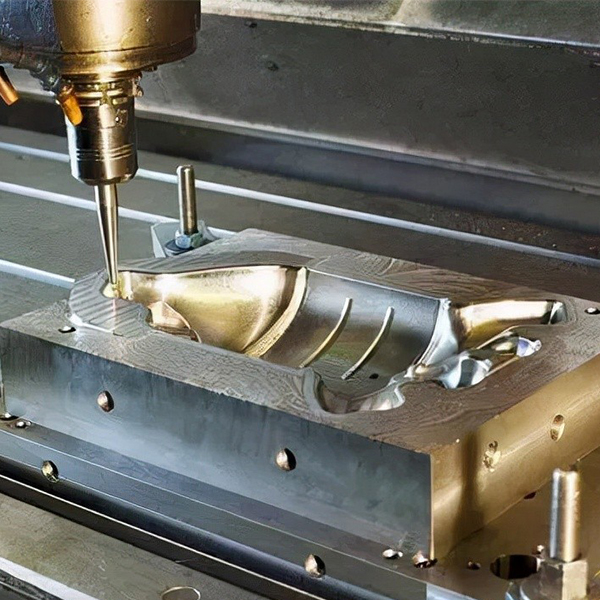

Mold steel can be roughly divided into three categories: cold rolled mold steel, hot rolled mold steel and plastic mold steel.

Mold steel is used to make cold mold, hot forging mold, mold casting mold and other steel types. Molds are the main processing tools for manufacturing parts in machinery manufacturing, radio instruments, motors, electrical appliances and other industrial sectors. The quality of the mold directly affects the quality of the pressure processing technology, the accuracy of the product, and the production cost. The quality and service life of the mold are mainly affected by the mold material and heat treatment, in addition to the reasonable structure design and processing accuracy.

1.Material: Cr12, DC53, SKD11, D2, P20, 718, Nak80, S136, as per customer’s requirement

2.Packing: standard sea-worthy packing

3.Surface treatment: punched, painted or as per customer’s requirement

4.Size: as per customer’s requirement

Different materials have different characteristics:

1.45# High-quality carbon structural steel, the most commonly used medium-carbon quenched and tempered steel

2.Cr12 commonly used cold work mold steel (American steel number D3, Japanese steel number SKD1)

3.DC53 commonly used cold work mold steel imported from Japan

4.DCCr12MoV-wear-resistant chromium steel

5.SKD11 tough chromium steel

6.D2 high carbon and high chromium cold work steel

7.P20 Generally required size plastic mold

8.718 high-demand large and small plastic molds

9.Nak80 High mirror surface, high precision plastic mold

10.S136 Anti-corrosion and mirror-polished plastic mold

11.H13 Ordinary common casting mold

12.SKD61 Advanced Casting Mould

13.8407 Advanced Casting Mould

When processing molds, because molds have a wide range of uses and the working conditions of various molds are very different, there is a wide range of materials for manufacturing molds, and mold steel is the most widely used mold material. From general carbon structural steel, carbon tool steel, alloy structural steel, alloy tool steel, spring steel, high-speed tool steel, stainless heat-resistant steel to maraging steel and powder high-speed steel that meet the needs of special molds, Powder high-alloy mold steel, etc. mold steel can generally be divided into three categories: cold work mold steel, hot work mold steel and plastic mold steel.

Application

As China metal materials industry leading enterprises, the national steel trade and logistics "Hundred good faith enterprise",China steel trade enterprises, "Top 100 private enterprises in Shanghai”. Shanghai Zhanzhi industry Group Co., Ltd.,(shorted to Zhanzhi Group) takes the" Integrity, Practicality, Innovation, Win-Win " as its sole operation principle, always persist in putting the customer demand in the first place.

- INTEGRITY

- WIN-WIN

- PRAGMATIC

- INNOVATION