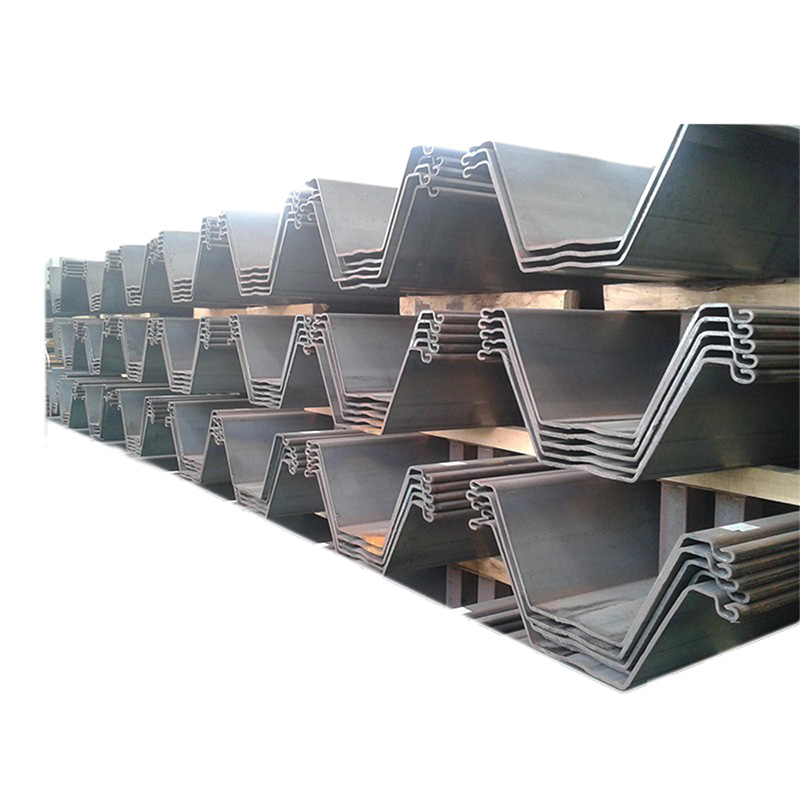

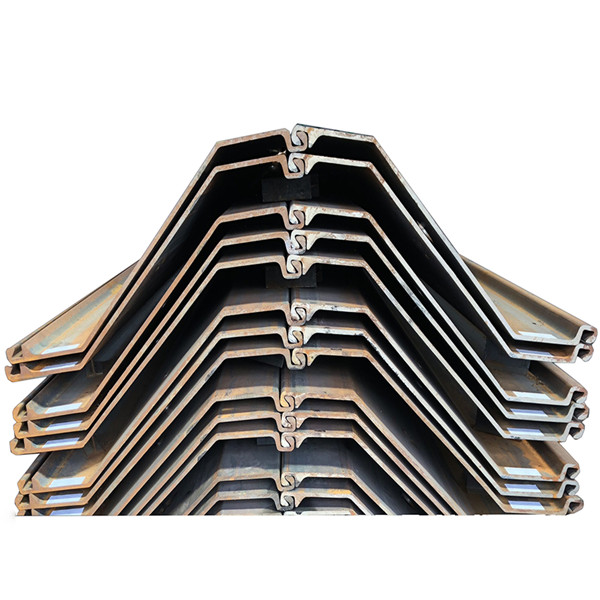

Steel Sheet Pile - Manufacturers, Factory, Suppliers from China

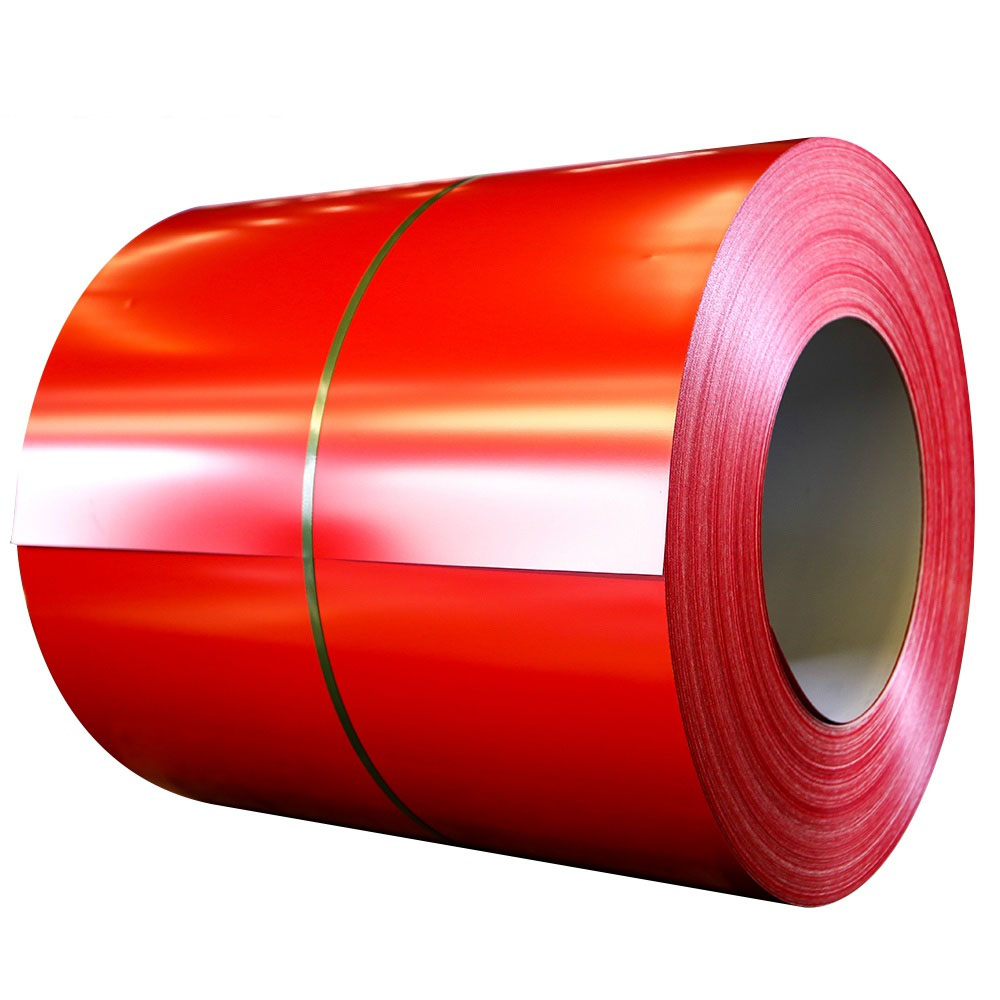

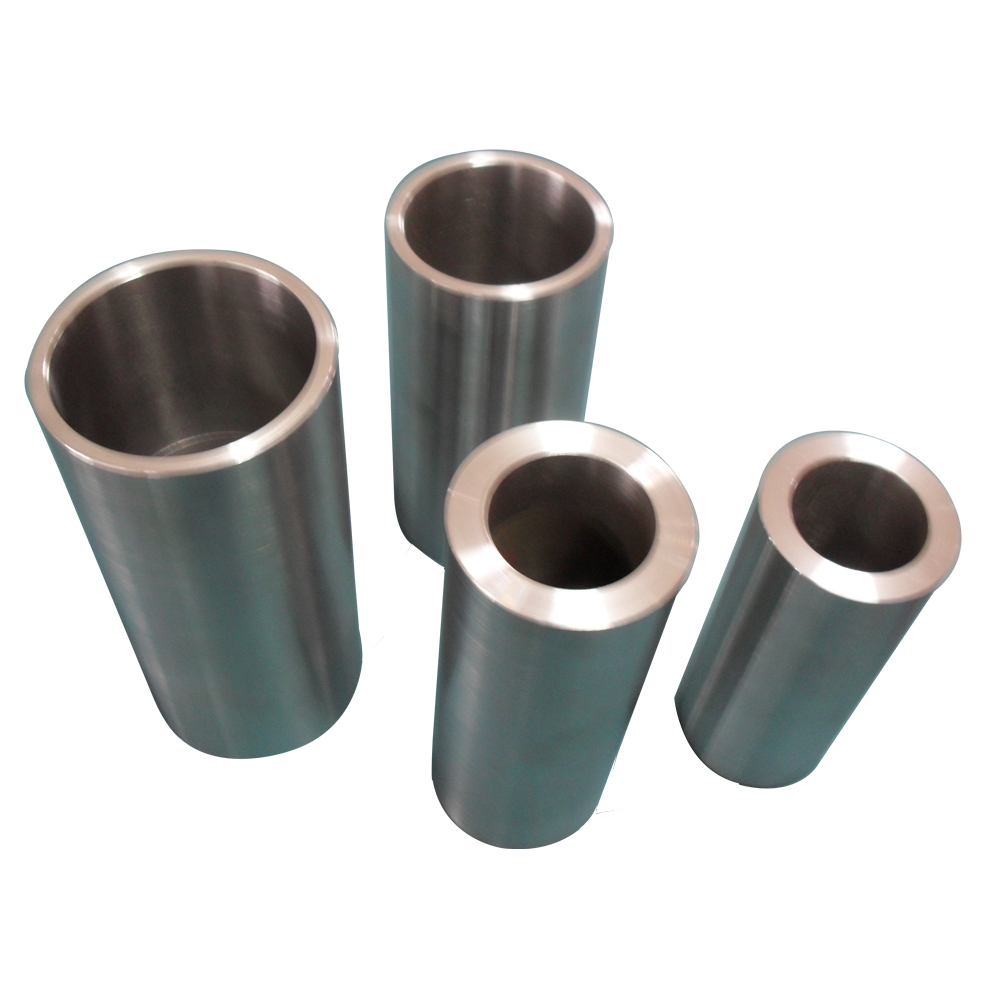

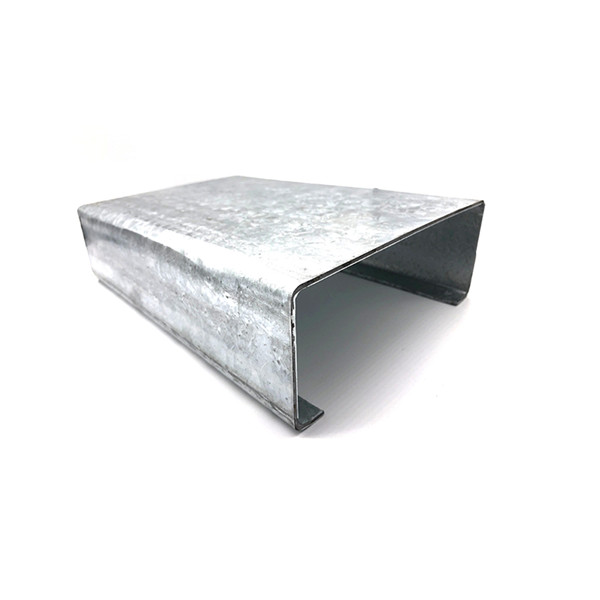

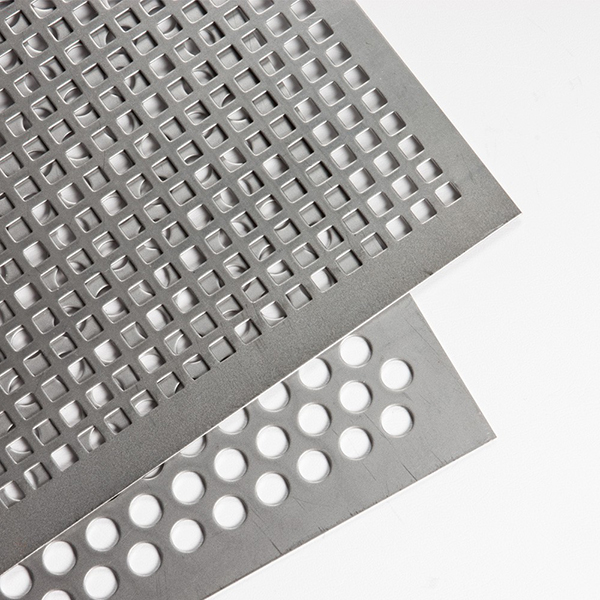

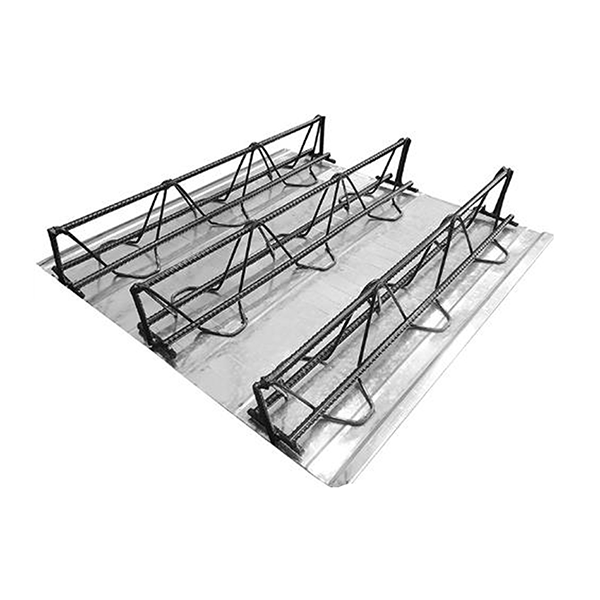

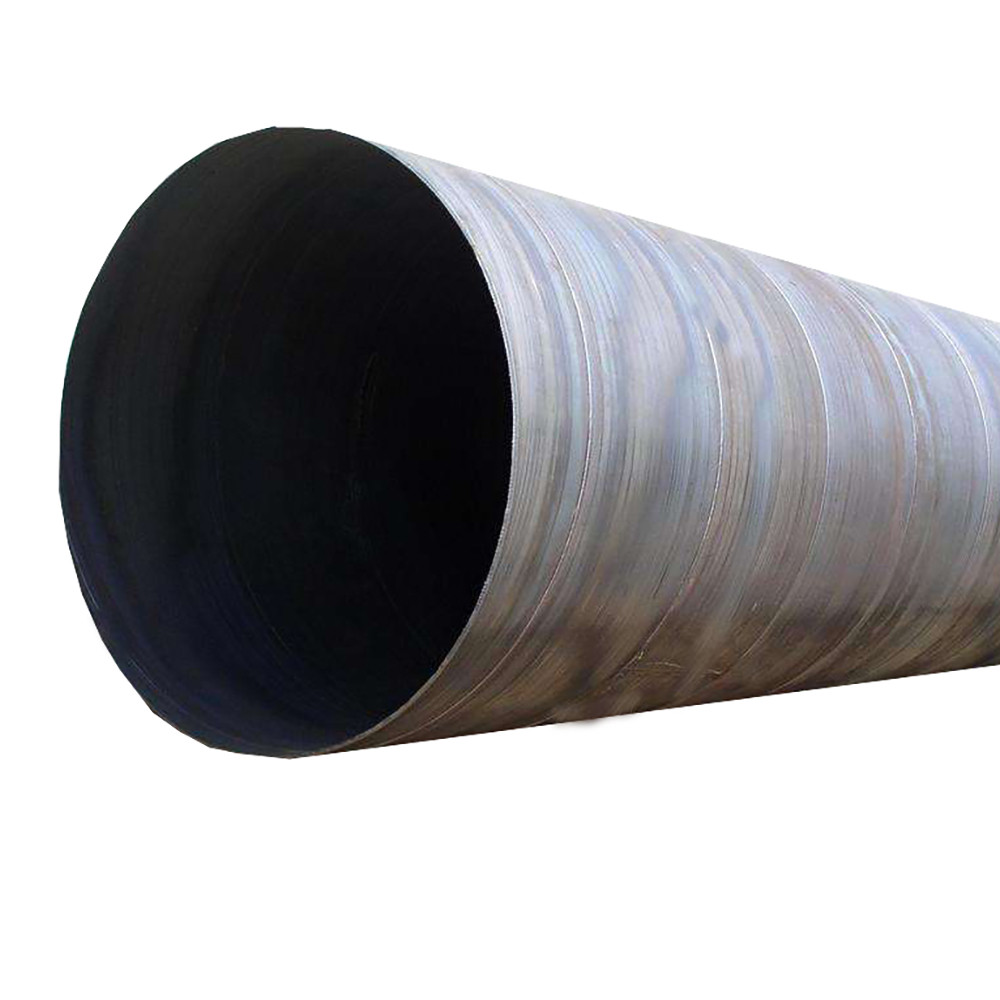

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for Steel Sheet Pile, Galvalume Roofing Sheet, Welded Steel Pipe, Zinc Aluminum Magnesium Coated Steel,Uic60 Steel Rail. Standing still today and looking into the future, we sincerely welcome customers all over the world to cooperate with us. The product will supply to all over the world, such as Europe, America, Australia,Israel, Cannes,Peru, Johannesburg.Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Related Products